Prepress

Prepress

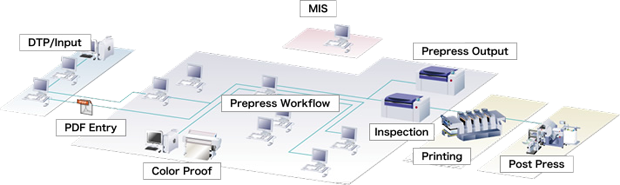

Fuji XMF RIP Workflow /

Screen Trueflow RIP Workflow

At Udayan Printing and Packaging we utilize an all PDF workflow and accept Adobe® InDesign® files. And we are determined to be progressive, continually investing in technology and equipment to insure the reliability, speed and consistency of the files we process.

3 x Epson 9900 / 2 Epson 9880 / HPZ 6200

This certified profiles we generated for our presses is used in our proofing system to adjust each proof to match the press it will run on, virtually minimizing differences from the proof to the press.

By using the same “ripped” and positioned file for our colour and folded proof as we use for outputting plates, so there is no behind the scenes changes with the files you will approve. What you see is literally what you will get.

2 x Plate Setters

All of our presses has been finger printed and the profiles loaded into our workflow for file processing. Each file that is “ripped” is adjusted for the exact press it will run on ensuring the optimum colour gamut that each press is capable of printing. But we didn’t stop there. Our file processing system sends the colour data for each job to the press it is to be run on so that the press will have all the colour data needed to run the job accurately and consistently, with less time needed for make ready. This means less time wasted for you on Press Approvals, and prints that the first piece will match the last.

Become a dealer today

Register now for free to become a trade print broker and take advantage of our state of the art trade printing equipment!